A life in a photobooth.

Restoring Pipes and Reclaiming Lives

The musings of a pipe smoker

Peterson Pipe Notes: Shapes, Lines & Series

Tobacco and Pipe Reviews for the Common Smoker

A Beautiful Cigar Touches All My Senses ™

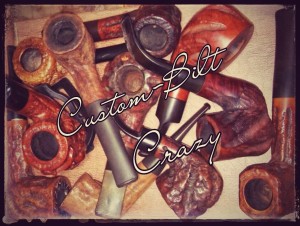

tobacco pipe refurbishing

From Revival To Survival

Pipes Cigars & Musings

A life in a photobooth.

Restoring Pipes and Reclaiming Lives

The musings of a pipe smoker

Peterson Pipe Notes: Shapes, Lines & Series

Tobacco and Pipe Reviews for the Common Smoker

A Beautiful Cigar Touches All My Senses ™

tobacco pipe refurbishing

From Revival To Survival

Pipes Cigars & Musings

Outstanding stem repairs on this one! Great work all round – that’s a good looking pipe now.

LikeLike